I made ChatGPT write a blog post about ChatGPT

I asked the ChatGPT AI to write a blog post about ChatGPT

I asked the ChatGPT AI to write a blog post about ChatGPT

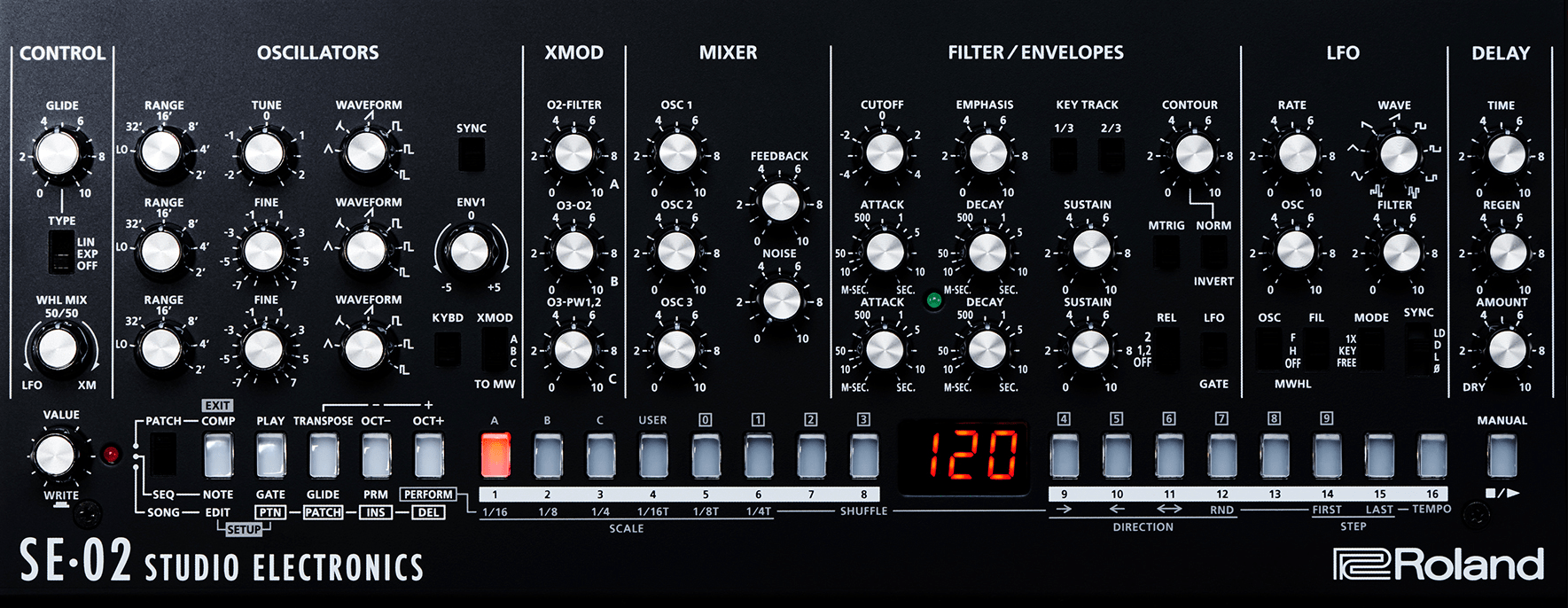

A major miss by Roland on the JU-06a Boutique - the external clock sync does not trigger held notes when the arpeggio function is enabled. This unfortunate, as it is a feature that exists in many (all?) other Boutique stynth models.

I got tired of having to click through several (slow loading) pages to check for Boutique firmware updates for several units. As such, I created a tool that checks daily and builds a single summary page (with links!) for the latest firmware updates for each model.

UPDATE! I whipped up a new batch of these for sale -> Check my Reverb Shop https://reverb.com/shop/very-sound-gear

So, I’m new to synthesizers.

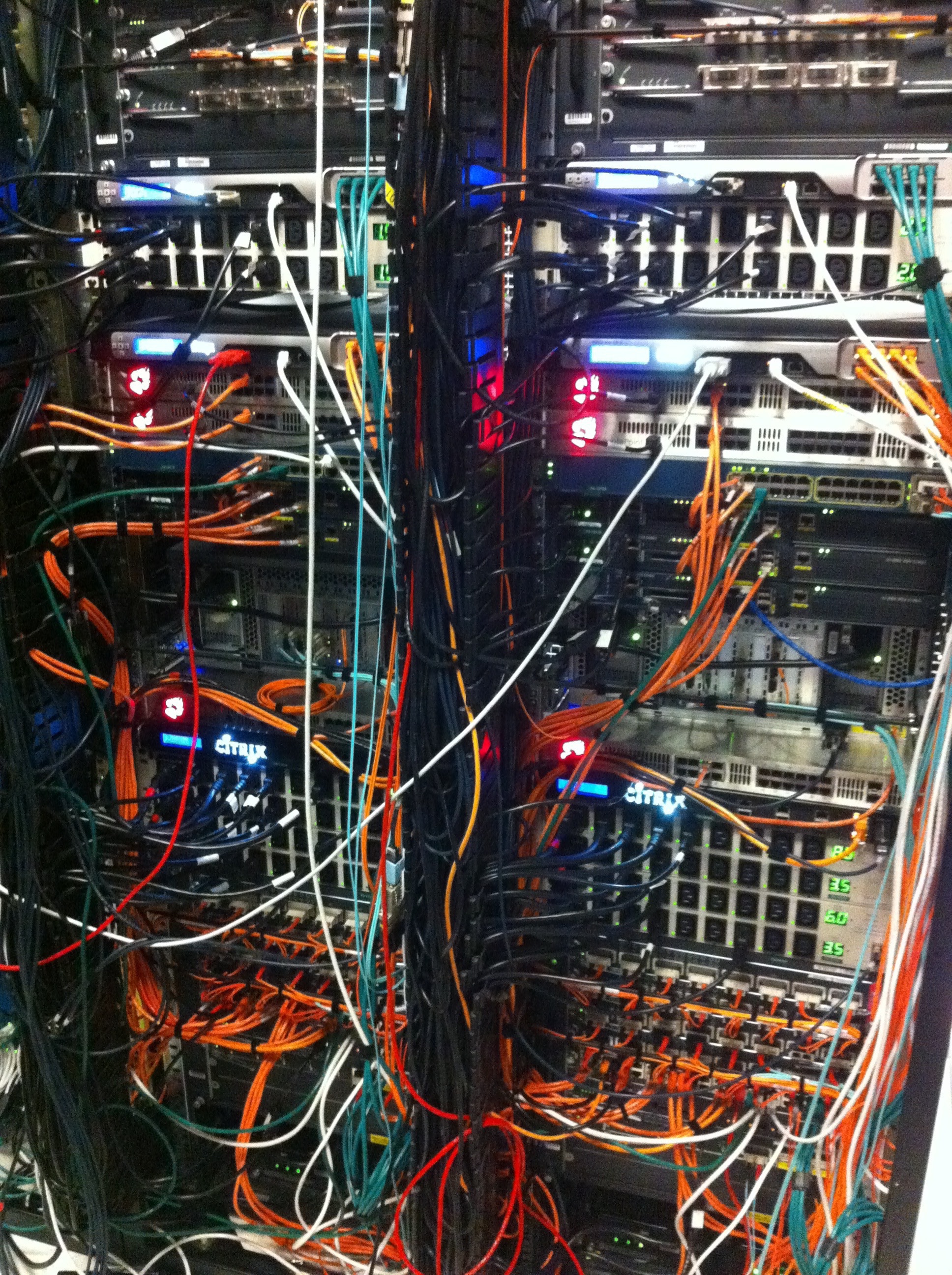

I love that my pfSense router can manage Acme certificates for my local domain. I use DigitalOcean for hosting this blog, so I was able to configure pfSense manage my Acme certificate updates using a DNS Challenge controlled through DigitalOcean’s API (with a key).

or… how I stopped worrying and learned to love containers…

After I migrated blog engines, I failed to realize that I killed my old minipov code generator tool. I got it working again (in a new location):

I was making it to sell, but I think I’ll keep it. It’s splendid.

Ok, so I found a neighbor that was able to get the welding done for me.